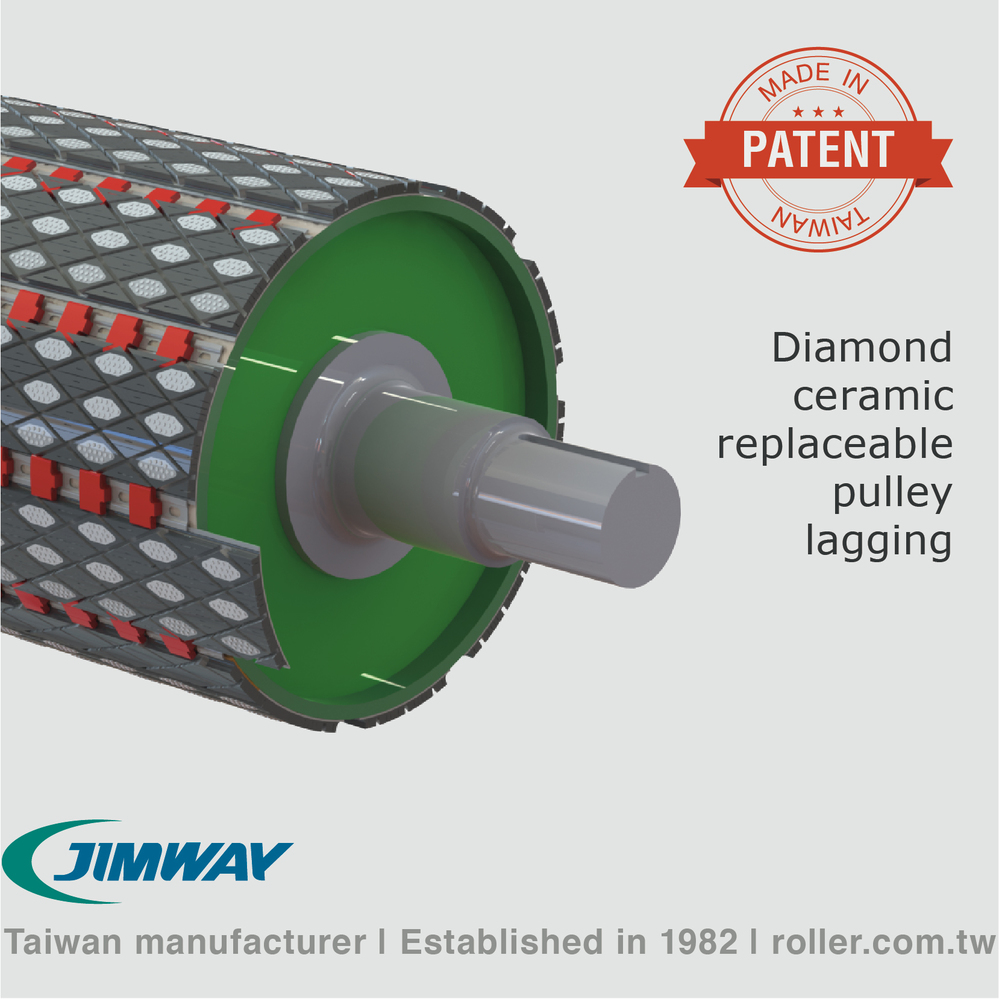

Diamond Ceramic Replaceable Pulley Lagging

▪ Extremely high friction coefficient

▪ Less system downtime

▪ Lifetime extension

▪ Less material build up

JIMWAY'S REPLACEABLE LAGGING WITH PATENTED RETAINER THAT REDUCES THE VIBRATION OF THE CLEANER'S BLADE AND NOISE TO IMPROVE CARRYBACK.

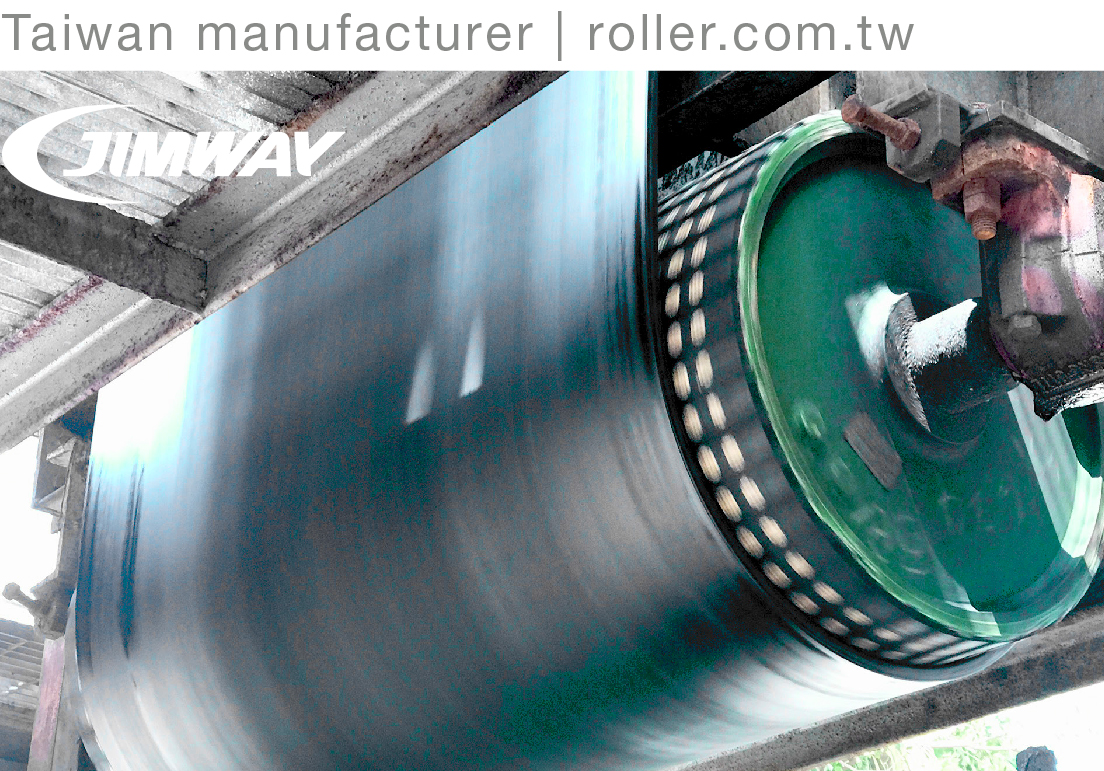

Replacing hot vulcanized lagging costs a lot because of hiring cranes and transport fees. Jimway's replaceable lagging provides a cost effective solution that the retainers are already in place to replace worn lagging, which become quicker and easier.

COMPARISON SHEET: VULCANIZED/REPLACEABLE PULLEY LAGGING

|

|

Vulcanized Pulley Lagging | Replaceable Pulley Lagging | ||

|

Hiring cranes is very expensive. After removing the pulley, transporting it to replace lagging causes downtime costs increased. |

Replaceable lagging can be installed on site. Since the retainers are already in place, replacement of worn lagging is quicker and easier. |

|||

|

|

|||

| Downtime |

|

Few days (3~5 days) |

|

Few hours (within a day) |

| Maintenance | Hiring cranes/working aloft | Replacing lagging on site |

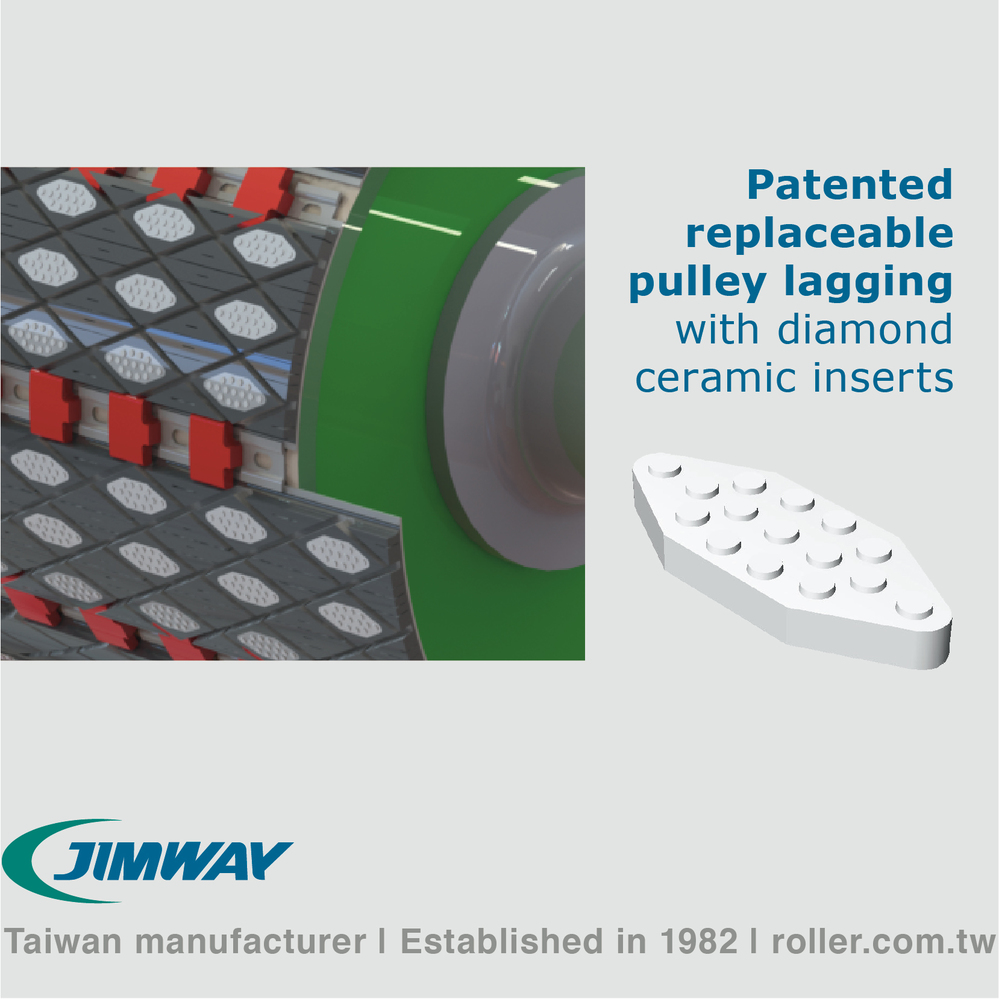

COMPARISON SHEET: RUBBER/CERAMIC PULLEY LAGGING

| Rubber Pulley Lagging | Ceramic Pulley Lagging | |||

|

Rubber pulley lagging protects the belt and the residue is on the inside of the belt withoutdamaging the pulley; however, belt mistracking may happen. |

Ceramic tiles are inserted into rubber pulley lagging to increase the friction and the wear resistance for the pulley's service life extension. |

|||

|

|

|||

| The Service Life | Shorter | 3X~5X service life | ||

| The Friction | Normal | >2X | ||

| Belt Mistracking | Easily happen | Rarely happen |

THE COEFFICIENT OF FRICTION

| Humidity of Material | The Coefficient of Friction between the Lagging and the Belt | |||||

| Bare Steel | Groove Rubber | Ceramic | ||||

| Dry | 0.30 | 0.40~0.50 | 0.70~0.80 | |||

| Wet | 0.10~0.20 | 0.20~0.25 | 0.40~0.80 | |||

| Mud | 0.10 | 0.18~0.20 | 0.40~0.50 | |||